Maintaining safe, efficient pharmaceutical operations during pandemic through innovation and remote technologies

(By Ravi Kalla)

In India, a unique, collaborative project is challenging conventional thinking on how pharmaceutical companies can approach convergence of IT and process automation technologies (OT) layers for remote operations, ) and mobile solutions.

- Advertisement -

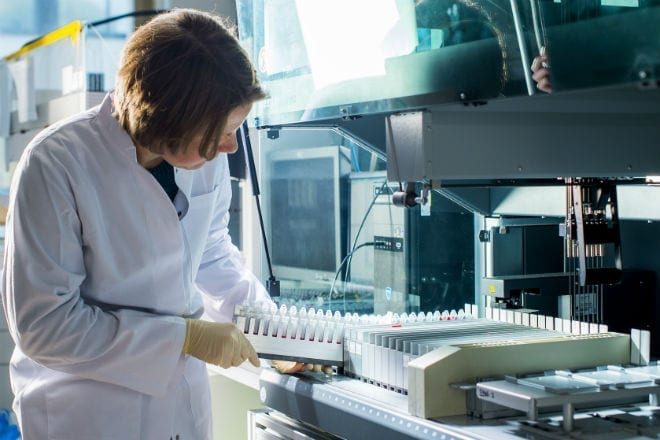

Installing an integrated system that combines API, fermentation, biologics and building management system, continuous monitoring system and environmental monitoring systems at its 15-acre pharmaceutical campus in Bangalore, has enabled Anthem Bioscience, a contract research organisation (CRO), to improve efficiency, high availability and accessibility of production systems during the recent pandemic – all with only a fraction of its workforce working on-site.

This is particularly relevant in light of worldwide lockdowns resulting from the current health crisis. The pharmaceutical industry is an essential service at the forefront of the battle to find a coronavirus vaccine. The imperative to find a vaccine has to also be carefully balanced with the requirement to continue an uninterrupted supply of various other medicines to the public.

Pharma is also one of the most heavily regulated industrial sectors. With the onus on companies to validate internal systems and protocols as per US FDA and other regulatory bodies’ norms, and fully comply with 21CFR Part-11, ISA 88 and GAMP V, digital solutions can help ensure end products consistently satisfy international standards.

Addressing workflow inefficiencies

Partnering with ABB, Anthem has developed an Industry 4.0 automation solution for API, fermentation and biologics manufacturing plants that unifies every aspect of the company’s operations in a single, scalable platform.

This not only streamlines regulatory compliance, it gives personnel unprecedented visibility along the entire production value chain, and enables real-time monitoring of assets using human-machine interfaces for informed decision-making, all while working on fixed terminals, remotely on tablets or mobile phones.

Manufacturing equipment including process equipment (upstream and downstream), clean and other utilities such as reactors, dryers, hydrogenators, nutrient dosing, media preparation, Buffer vessels, fermenters, bio-reactors, TFF, chromatography systems, lyophilizers, process water, plant steam generation and distribution systems, solvent distribution system are typically purchased from multiple OEMs, meaning multiple programmable logic controllers (PLCs) and SCADA systems – each with their own graphics, presentation and logics elements – are scattered throughout the plant in individual silos that operate simultaneously.

This results in more complex operations, integrations, customization, maintenance, manpower, training, qualification, lack of high availability and business continuity and more dependence on OEMs / vendors, makes it much more difficult for personnel to operate efficiently and get actionable data in and out of machines in a timely manner to use it in a consistent way.

Multiple hardware, network, storage and back-up systems associated with multiple PLCs also cost more than four to ten times depending on the complexities in terms of OPEX expenditure than employing a centralised system, and business continuity and high availability is always a conern. For example, in a typical PLC environment, in case of a failure, either the PLC / SCADA systems needs to be fixed /replaced and re-qualified as per GMP standards. This may take around 3-15 working days depending on various constrains. Losing the equipment for such a long period may result in a significant loss in terms of deliverables and revenues.

Integrated DCS and secure data centres

To address these issues, Anthem and ABB along with the equipment vendors-built logics, graphics and IT infrastructure, and unified it in a single platform for ease of use. Chemical API, biological and formulation manufacturing, and the building management system are all integrated. Monitoring and control of these critical systems are from ABB Ability System 800xA DCS from two data centres at Anthem’s Bangalore site.

Multiple data points relating to everything from humidity and temperature control and pure steam systems, to differential pressure in classified and unclassified areas is all part of the centralised DCS.

ABB Ability Manufacturing Operations Management (MOM) software gives key personnel access to this data at every stage of the production process – from material storage to manufacturing and dispatch – to facilitate analysis, reporting, production planning, and quality and asset management.

- Advertisement -

Having these elements in one unified system that delivers real-time visibility of entire processes to business users across the plants through ABB DCS system which is tightly integrated with Anthem IT infrastructure have reduced significant time and cost. This solution enabled Anthem workforce to work remotely and monitor the critical operations especially during pandemic situation.

This solution also helped Anthem to optimize the CAPEX and OPEX investments, increased availability, business continuity, reduced dependence on vendors significantly and many more advantages.

The benefits of virtualized architecture

The ABB DCS architecture including server, storage, and application software like SCADA/HMIs are virtualized. Using HMIs on tablets and smartphones, Anthem has maintained safe, efficient operations during the pandemic lockdown with just 10% of its IT and automation team, and 25% of its process team.

One of the unique capabilities of ABB Ability System 800xA is that it is not filtered or selective data. The virtualised architecture means staff can access the exact screen the plant operator is seeing in the control room – with the same granularity and in near real time – on an iPad or mobile device.

This means staff are able to monitor key parameters at Anthem’s Bangalore facility from their own homes, reducing the cycle time needed to analyze any potential issues and take corrective action.

By employing remote enabled solutions and integrating plant operations into a single localised DCS, Anthem also realised CAPEX savings of up to $9,000 per piece of equipment compared with buying multiple PLCs. Associated licence, hardware and maintenance costs were also significantly reduced.

In addition, the virtual architecture has enabled Anthem to reduce manpower in several business verticals, and because the project converges IT and OT, the CRO as invested heavily in cybersecurity.

Further adoption of Pharma 4.0

The project began in 2016 with ABB’s delivery of a chemical synthesis and fermentation solution in the chemical plant, followed in 2017 by an expansion of the fermentation system. The concept of a common integrated BMS was developed in 2016-, and last year, ABB delivered a unified distributed DCS and BMS for the additional biologics manufacturing plant at Anthem’s manufacturing campus in Bangalore.

The starting point for the project in 2016 was to challenge the status quo and established norms of how a pharma project is executed. This involved increasing the availability and modularity of the solution, reducing costs and footprint, and looking at how to manage a large DCS with fewer people.

Four years on, Anthem has realized its ambition of making plant operations available to its staff on either a tablet or mobile phone. A key element of this strategy is IT and OT integration, whereby staff have complete insight of factory operations, processes and real-time data while working remotely. This solution will enable anthem’s future digital strategy of artificial Intelligence /Machine learning and predictive manufacturing processes.

Adoption of such technologies is set to continue in the pharmaceutical industry, particularly in the area of predictive manufacturing. In addition, being able to retrieve data more easily and quickly in this way also makes auditing much easier and helps to bring lucrative products to market quicker.

The unprecedented challenge presented by the pandemic provides a huge opportunity for businesses within the pharmaceutical industry to continue to challenge existing business practices and identify areas for innovation using automated and digital solutions.

(The author is the Head, Information Technology, Automation and Instrumentation at Anthem Biosciences Private Limited)

If you have an interesting article / experience / case study to share, please get in touch with us at [email protected]

Advertisement